EC Fan Upgrades for Energy Efficiency

Did you know that HVAC equipment can often account for more than 40% of a commercial building’s energy consumption? Fortunately there are simple ways to significantly improve the energy efficiency of your HVAC equipment, without having to replace full units.

Installations have shown that by replacing AC fans with an EC fan upgrade, you can optimise your air handling unit for ultimate energy efficiency, potentially reducing your energy usage by up to 70%.

If you want to minimise energy consumption by replacing less efficient fans and motors, you have a number of options:

1. Direct motor replacement with current high efficiency AC motors, which can alone provide energy savings of around 20%.

2. Replacement of older, less efficient forward curved fans with high efficiency backward curved or aerofoil blade fans.

3. Modification of inefficient, costly belt drive fans with modern direct drive fans, either AC, PM or EC, with suitable speed control. Upgrading from belt driven fans to a direct drive solution could reduce ongoing maintenance costs by up to 80%

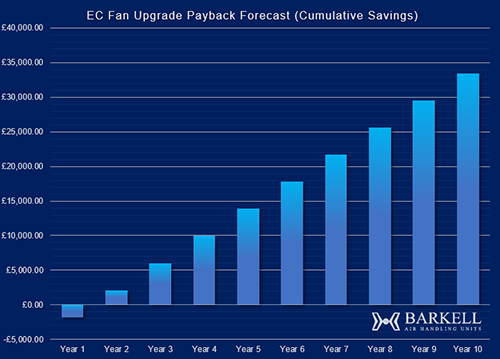

By adding variable-speed AC motors, PM motors or EC fans to the AHU, we predict that you could save between 30 and 60% on annual electricity costs.

Why upgrade with Barkell?

Barkell Ltd have almost 40 years experience in the manufacturing of AHUs, and we have a team dedicated to AHU refurbishment and energy upgrades. Our engineers are capable of carrying out fan upgrade works on AHUs from any manufacturer, not just Barkell units.

There are many factors involved in selecting the ‘right’ fan for your application, and an essential one is knowing your operating point. Barkell can work with you to find out what your operating point is (target air flow rate in cubic metres per second (m³/s) against the system resistance in Pascals (Pa)).

We will also work with you closely to identify your design goals. While the operating point of the fan defines the most important variable, power consumption, and (dependent on application) noise reduction, are also huge drivers. For example: If noise is a critical factor for you, the best solution is usually a larger fan running at the lowest possible speed.

Barkell are used to working within a variety of space and access constraints. Selection of the right fan must consider the available space within the AHU, and the most efficient or quietest fan may not fit within the available space. Fan selection is not a ‘one-size-fits-all’ approach, it’s a fine balance between exisiting variables. The key to success in finding the right fan is to identify which model results in the fewest compromises.

“Fan technology has come a long way in the last 20 years. This coupled with the fact that a fan’s performance will naturally degrade over time means that retrofitting AHUs with newer fans is one of the easiest ways to save on energy costs.

Sometimes due to site constraints and Ecodesign regulations it’s simply impossible to replace aging equipment with new so retrofits and upgrades are a really important part of our offer to clients. We handle everything from an initial free-of-charge site survey from which we will be able to give you a good idea of pay-back periods and ongoing savings. It really is as simple as that so if customers have an AHU system over 10 years old they should get in touch with us and there’s a really good chance we could save them money” – Richard Gordon, Barkell Commercial Manager